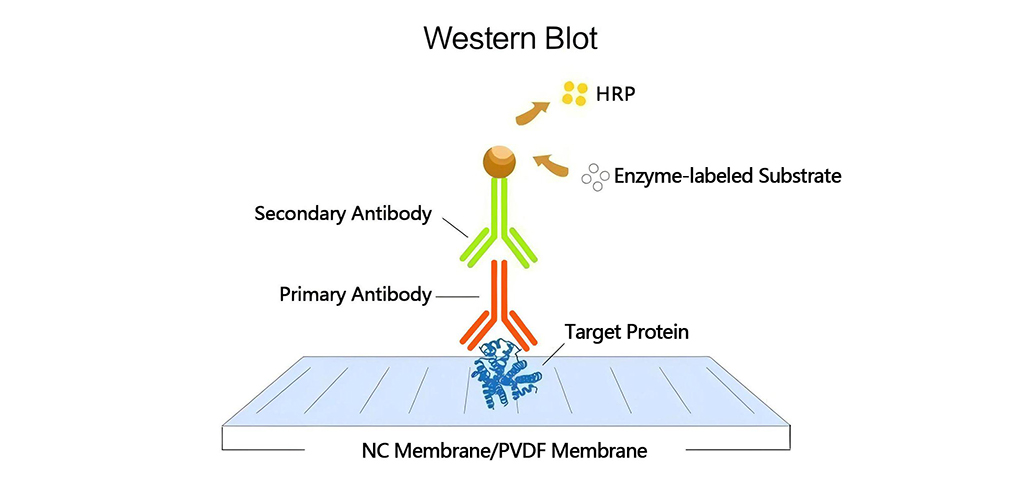

Q1: What is the fundamental principle of Western blotting?

A: Western blotting (WB) is an immunodetection technique that involves:

- Electrophoretic separation of proteins by SDS-PAGE

- Electroblotting transfer to solid-phase membranes (nitrocellulose or PVDF)

- Immunoprobing with target-specific primary antibodies

- Detection using enzyme-conjugated secondary antibodies

The technique provides specific protein identification through antigen-antibody interactions, with applications ranging from protein expression analysis to diagnostic testing.

Q2: Why is methanol pretreatment required for PVDF membranes?

A: PVDF membranes require methanol activation because:

- PVDF is intrinsically hydrophobic (contact angle >100°)

- Methanol (50% v/v) reduces surface tension, enabling aqueous buffer penetration

- Optimal treatment involves:

30 sec immersion for wet transfer

15 sec for semi-dry transfer

Subsequent equilibration in transfer buffer (5 min)

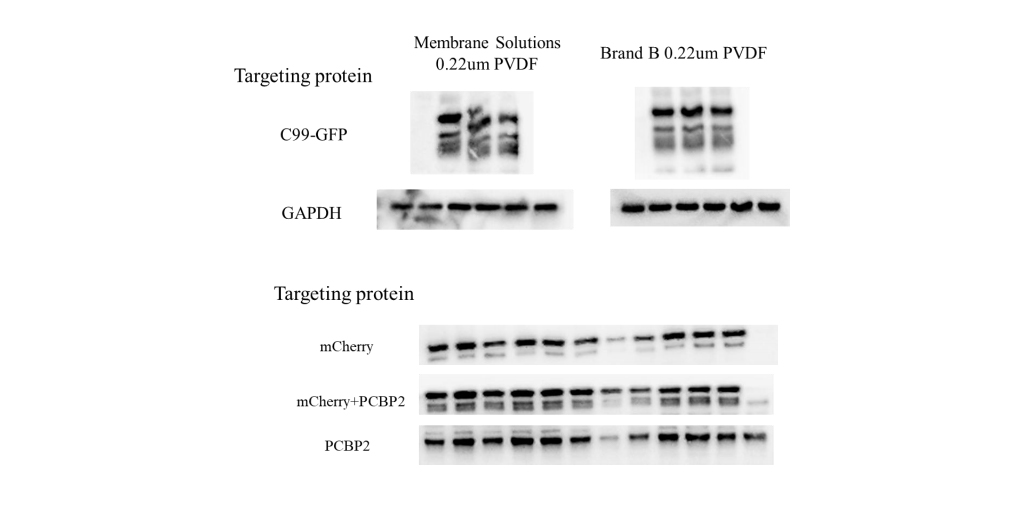

Q3: How to select appropriate membrane pore size?

A: Pore size selection criteria:

Parameter | 0.2 μm PVDF | 0.45 μm PVDF |

Protein size | <20 kDa (90% retention) | >20 kDa |

Binding capacity | ~200 μg/cm² | ~150 μg/cm² |

Resolution | High | Moderate |

Flow resistance | High | Low |

Q4: What are the recommended transfer conditions?

A: Optimal transfer parameters:

- Buffer composition: 25 mM Tris, 192 mM glycine, 20% methanol

- Current: 200-300 mA (constant)

- Duration: 60-90 min for 10% gels

- Temperature: Maintain at 4°C

- For small proteins (<20 kDa):

- Reduce methanol to 10%

- Decrease transfer time to 30 min

- Use 0.2 μm PVDF membrane

Q5: How to verify transfer efficiency?

A: Recommended verification methods:

- Reversible staining:

- Ponceau S (0.2% in 1% acetic acid)

- Sensitivity: 0.5-1 μg/band

- Compatible with subsequent immunodetection

- Irreversible staining:

- Coomassie Brilliant Blue

- Sensitivity: 0.05 μg/band

- Destructive to membrane

Q6: What are the key differences between PVDF and NC membranes?

A: Comparative analysis:

Characteristic | PVDF Membrane | NC Membrane |

Mechanical strength | 40-60 MPa | 10-15 MPa |

Chemical resistance | pH 1-13 stable | Degrades at pH extremes |

Temperature range | -70°C to 150°C | -20°C to 40°C |

Protein binding | Hydrophobic interaction | Non-covalent adsorption |

Cost | $0.8-1.2/cm² | $0.3-0.5/cm² |

Q7: How to properly store blotted membranes?

A: Recommended storage protocol:

- Sandwich membrane between filter papers

- Place in sealed plastic bag with desiccant

- Storage conditions:

- Short-term: 4°C (≤2 weeks)

- Medium-term: -20°C (≤2 months)

- Long-term: -70°C (years)

Critical note: Never allow membranes to dry if intending for reprobing

Q8: What are the troubleshooting solutions for common WB issues?

A: Technical solutions:

- High background

- Cause: Insufficient blocking

- Solution: Extend blocking time (1 hr with 5% BSA) or use protein-free blockers

- Weak signal

- Cause: Over-diluted antibodies

- Solution: Perform antibody titration (recommended range: 1:500-1:5000)

- Poor transfer efficiency

- Cause: Improper membrane selection

- Solution: For small proteins (<20 kDa):

- Use 0.2 μm PVDF

- Reduce transfer time to 30 min

- Decrease methanol to 10%

- Non-specific bands

- Cause: Antibody cross-reactivity

- Solution: Include control lysates and validate antibodies

Q9: When should PVDF vs NC membranes be selected?

A: Selection guidelines:

Choose PVDF when:

- Detecting small proteins (<20 kDa)

- Operating in harsh conditions (organic solvents, extreme pH)

- Requiring membrane reprobing (>5 cycles possible)

- Needing long-term archiving

Choose NC when:

- Working with large proteins (>30 kDa)

- Using fluorescence detection

- Operating under budget constraints

Q10: What are the critical steps for successful protein transfer?

A: Essential protocol:

- Membrane preparation

- PVDF: Methanol activation (30 sec)

- NC: Direct equilibration in buffer

- Transfer stack assembly

- Eliminate all air bubbles using roller

- Maintain proper orientation (gel→membrane→filter paper)

- Transfer conditions

- Constant current: 200-300 mA

- Cooling: Ice bath or chilled circulator

- Duration: 1 hr per 1 mm gel thickness

- Post-transfer validation

- Ponceau S staining (reversible)

- Coomassie staining of residual gel (destructive)

Leave a Comment

Your email address will not be published. Required fields are marked *